Beams are among the most important structural elements of a building or structure. They form part of its skeleton and prevent it from breaking.

Table of Contents

ToggleThey provide support for buildings, bridges, flyovers, and other structures. These horizontal or inclined supports help distribute weight and forces, keeping everything stable and safe. Whether a tall skyscraper or a complex-curvy bridge, the type of beam chosen is decisive for the project’s strength and durability.

So today, we are going to take a closer look at 25 different types of beams used in construction based on the way they are supported, the materials used, and much more. We will also explore their applications and when each beam type is suitable for which structures. Let’s start!

What are Beams?

As you have just read, beams are structural elements in almost every type of construction. They are specifically designed to carry transverse loads, i.e., loads that act perpendicular to the length of the beam, as in a cross. Their main function is to transfer the structure’s weight to the columns or any other support points. Thus, it prevents the structure from deforming or collapsing and falling down.

That is why we cannot stop talking about their importance since they are part of the “skeleton” of buildings, bridges, roofs, and many other types of construction. With them, it would be easier to promise that a building could stand; they play a critical role in the integrity and stability of structures. They are the invisible pillars that support various structures’ weight, distributing the load efficiently and preventing deformation or collapse.

Because different types of beams exist in civil engineering, it is essential to know the right one, depending on what is being built, the structure’s needs, and the environment in which it will be located. You must not only focus on aesthetics but also on practicality.

What are the Uses of Beams?

You already have some clues, but the use of beams in both engineering and construction is varied. Among them, we can find that they are used for:

- Load bearing: The primary function of all types of beams is to support loads, whether the weight of a structure such as a roof, equipment, or vehicles, or even live loads such as people. They are responsible for distributing this weight along their length and transferring it to the points of support.

- Prevent deformation: Beams prevent a structure from deforming or sagging under load. By distributing and balancing loads, they maintain the integrity of the structure.

- Reduce the gaps: Beams allow structures to be built with large spans, i.e., a large space between supports. Without them, you could not enjoy wide, open spaces in buildings or rooms.

- Resist seismic loads and wind: These elements contribute to the stability and resistance of a structure to adverse environmental conditions such as earthquakes, strong winds, and even hurricanes. They achieve this by distributing the forces that exert pressure in a balanced way, making it more difficult to find a weak point where a crack could form.

Different Types of Beams in Construction

We will classify different types of beams in civil engineering based on:

- Support Types

- Materials

- Cross-sectional Shapes

- Equilibrium

- Construction Methodology

- Geometry

Let’s explore all of them in detail:

Beam Types Based on Support Types

1. Simple supported beam:

Resting on two supports at its ends, this is your basic beam. It’s like a bridge between two pillars. When you put weight on it, it bends in the middle. Extremely common in construction because it’s simple and will do the job in many situations.

2. Cantilever beam:

Think of a diving board—that’s a cantilever beam. It’s fixed at one end and free at the other. Quite cool for making overhangs or balconies. It can take a lot of weight, but you have to be careful about how much stress builds up where it’s attached.

3. Fixed beam:

This one is fixed at both ends. No rotation, no movement. It’s super rigid and can take heavy loads without much bending. You’ll see these in large structures where stability is key. They are more difficult to install, but are strong among different types of beams!

4. Overhanging beam:

Imagine a beam that extends beyond its support on one side. It’s like a diving board but with extra support. You might see this on roof eaves or balconies. It’s tricky to balance because the forces on each side of the beam are different.

5. Double overhanging beam:

This is like the big brother of the overhanging beam. It sticks out beyond its supports at both ends. Think of a seesaw, but imagine it’s part of a building. It’s great for creating interesting architectural features, but you have to get your calculations right.

6. Continuous beam:

This is the marathon runner of beams. This type of beam spans more than two supports or spans multiple columns, distributing loads evenly along their length. You’ll often see them in bridges or long corridors. They’re efficient because they distribute the load well, but they can be a bit of a headache to analyse.

7. Trussed beam:

Think of this as a beam with superpowers. It’s reinforced with a triangular structure at the top or bottom. They can span long distances and carry heavy loads without being super thick. Additionally, you’ve probably seen them in large warehouses or gyms. Pretty clever engineering, if you ask us!

8. Plinth beam:

A plinth is a strong concrete beam between a wall and its foundation. Its purpose is to stop cracks from spreading from the foundation into the wall if the foundation shifts or settles.

Types of Beams Based on Materials

9. Timber beam:

It is inexpensive, easy to work, and suitable for moderate-load applications. However, its strength and durability are inferior to other materials.

10. Steel beam:

Steel is one of the most common structural materials. It is strong, durable, and versatile. Beams made from this material are ideal for heavy-duty applications such as bridges and skyscrapers.

11. Reinforced concrete beam:

These are a combination of concrete and steel reinforcement bars. This material is widely used in the construction of buildings and bridges due to its strength and durability.

12. Aluminium beam:

Aluminium is a lightweight and corrosion-resistant material, making it perfect for applications in environments where humidity is a key factor. Civil engineers widely use aluminium beams in marine and aerospace structures.

13. Pre-stressed concrete beam:

A variant of reinforced concrete, pre-stressed concrete beams are fitted with reinforcing bars that are tensioned before the concrete is poured. This process increases their strength and also allows engineers to create thinner and lighter beams.

14. Composite beam:

When engineers combine two or more materials—such as steel, plastic, and concrete—they create a composite beam. This beam has a very high strength-to-weight ratio, but it usually remains lighter than other beams. You can find them in high-rise buildings where they reduce the need for concrete and save on maintenance.

Types of Beams Based on Construction Methodology

15. Precast concrete beam:

Civil engineers construct these beams before construction and transport them to the site where the architectural project is taking place.

16. In-situ concrete beam:

These beams are poured directly at the construction site. This process involves setting up the formwork, placing reinforcement bars (rebar), and then pouring the concrete. These beams can be shaped to meet specific requirements, but they need time to cure. They are useful for customised fits.

17. Post-tensioned concrete beam:

Post-tensioned concrete beams use a technique that compresses the concrete before it carries any load. This is achieved by tensioning steel cables within the beam. As the cables attempt to return to their original length, they compress the concrete, resulting in a beam with increased strength and resistance to cracking. These beams are used in the construction of bridges and parking structures.

18. Lintel beam:

A lintel beam acts as a structural support over door and window openings, distributing the weight of the material above. The absence of lintels can compromise the integrity of these openings. Additionally, Lintels can be made of timber, steel, or concrete, and in some historic buildings, decorative stone lintels can add an aesthetic element. Not only do they have an important structural role to play, but they can also contribute to the overall design of a space.

Based on Cross-sectional Shapes

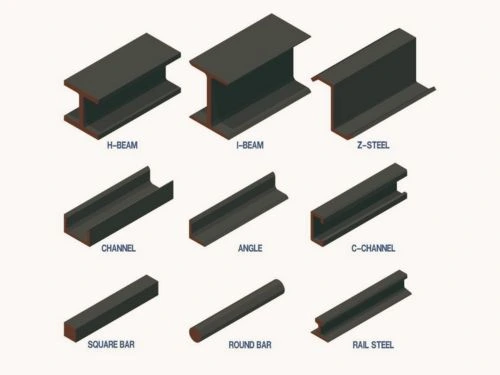

19. I-beam and H-beam:

The characteristic feature of these types of beams is that they have an “I” or “H” shape, from which they derive their name. They are ideal for carrying heavy loads and are often used in the construction of bridges and skyscrapers.

20. T-beam:

Imagine a capital T turned upside down. That’s your T-beam. It’s like a regular beam with a flat slab on top. This shape is great for floors in buildings because the top can be part of the floor itself. It’s efficient—you get more strength without using tonnes more material.

21. C-beam:

This looks like a C when you look at it from the end. It’s got a web (the vertical part) and two flanges (the horizontal parts). C-beams are also called channel sections and are very versatile. They’re good at resisting bending and twisting, which makes them popular in steel construction. You’ll often see them in industrial buildings or as part of larger structures.

22. L-beam:

As you might guess, this one is shaped like an L. It’s basically a beam with an extra bit sticking out at 90 degrees. This shape comes in handy when you need support in two directions at once. Think of the corner of a staircase or balcony—an L beam could take the vertical load as well as help support the edge of the floor.

23. Rectangular beam:

This is your classic, no-frills beam. It’s just a long cuboid—like a stretched-out box. Simple but effective. You’ll find them everywhere, from houses to large commercial buildings. They’re easy to make and calculate, which is why they’re so common. Sometimes the simplest is the best!

Types of Beams Based on Equilibrium Conditions

24. Statically determinate beam:

This is the ‘easy math’ ray of the engineering world. You can work out all the forces and reactions using just the equations of static equilibrium. It’s like a simple jigsaw puzzle where all the pieces fit together. These beams usually have only as many supports as they need—no more, no less. Engineers prefer them because they’re easy to analyse and design.

25. Statically indeterminate beam:

Now we’re in the “brain teaser” area of beams. Statically indeterminate beams have more supports or restraints than you really need, which means you can’t just solve for all the forces using equilibrium equations. They’re harder to analyse, but they can be stronger and more efficient. Continuous and fixed-end beams often fall into this category. They keep structural engineers on their toes!

Conclusion

FAQs

Q. How many types of RCC beams are there?

A. There are three types of reinforced concrete beams: Single-reinforced beams, Double-reinforced beams, and Flanged beams.

Q. How many types of I-beams are there?

A. There are two standard I-beam forms:

- Rolled I-beam, formed by hot rolling, cold rolling, or extrusion, depending on the material.

- Plate girder, formed by welding (or occasionally bolting or riveting) plates.

Q. What is the strongest beam type?

A. Beam strength depends on materials and design. Steel-reinforced beams are very strong and can carry a lot of weight, making them one of the best options for construction. However, it is best to ask an engineer which type of beam is suitable for your project.

Q. Are beams and pillars the same?

A. No, beams and pillars are not the same. Beams are horizontal or sloping and bear the load. Pillars or columns are vertical and support the beams.

Q. Which type of beam is economical?

A. Simple supported beams are often the most economical choice for small to medium-span structures. They are easier to build and use fewer materials.